Introduction to HISTRON

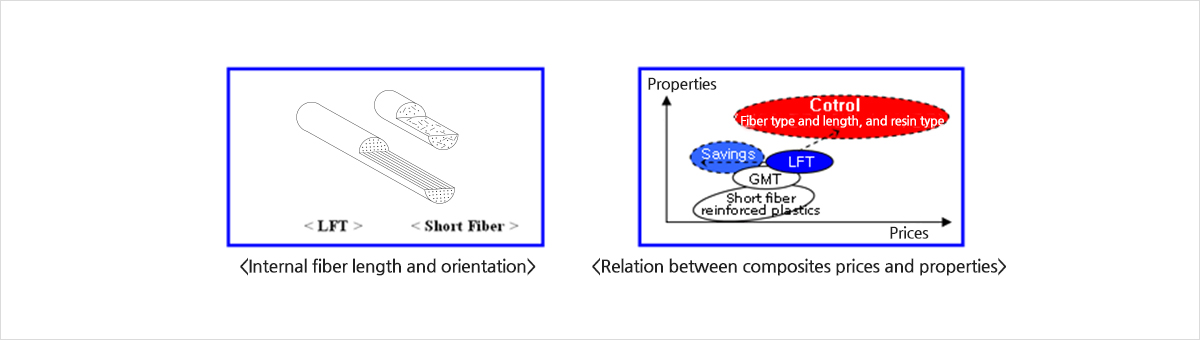

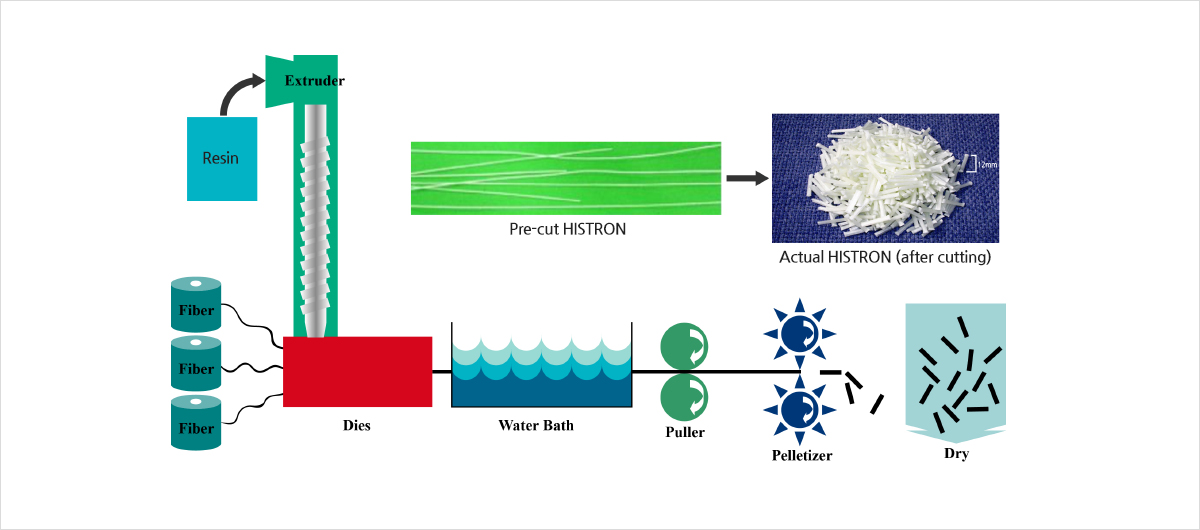

HISTRON is made by impregnating fiberglass into thermo plastics in a way similar to pull-out testing and then cutting them into pellets of the desired length, so that it can be injection molded.

Fiberglass can constitute up to 70% of HISTRON, and the amount of fiberglass contained can be adjusted by mixing HISTRON with resin during molding. In addition, when used as masterbatch, it can lead to cost reductions. The molded product’s fiberglass maintains its long length, which allows the molded product to have good mechanical strength compared to those made from other composites reinforced with short fibers (about 3mm), with its impact strength being particularly excellent . HISTRON is a material with higher levels of strength and rigidity than existing short –fiber reinforced materials, and it makes it possible to produce thin, high-strength molded products with less weight. In addition, it also leads to a shorter molding cycle.

Application of HISTRON

Auto Parts

Door modules, frontend modules, chair shells, mirror brackets, fans, bumper back beams, engine under covers, housing parts, under hood shrouds and fans, and roof handle switches and expanding

Industrial Parts

Pipe wrench parts, conveyor joints, carrier pedals, window handles, chain gears, flywheel gears, hose bands, nails for fixing insulations, Industrial fans, optical cable protection housings and junction boxes, and hot water caps.

Comparisons between HISTRON and Other Materials

Comparisons of properties between PP (polypropylene) based composite molding materials

| Item | Unit | Test method (ASTM) | HISRTON (G40P2GB1N) | Short Fiber Compound | GMT | BMC | SMC |

|---|---|---|---|---|---|---|---|

| Fiberglass content | % | - | 40 | 40 | 40 | 18 | 28 |

| Specific gravity | - | - | 1.12 | 1.19 | 1.18 | 1.9 | 1.9 |

| Tensile strength | kgf/cm2 | D638 | 1,262 | 910 | 1,120 | 500 | 900 |

| Flexural strength | kgf/cm2 | D790 | 1,844 | 1,180 | 1,610 | 1,400 | 2,000 |

| Impact strength | kgfㆍcm/cm | D256 | 26 | 11 | - | 30 | 65 |

| HDT | ℃ | D648 | 156 | 145 | 155 | 220 | 220 |

The properties shown above are mid-values obtained in certain conditions according to each test specification.

The properties of BMC and SMC are in accordance with KS M 3015’s test specifications.

HISTRON Manufacturing Process

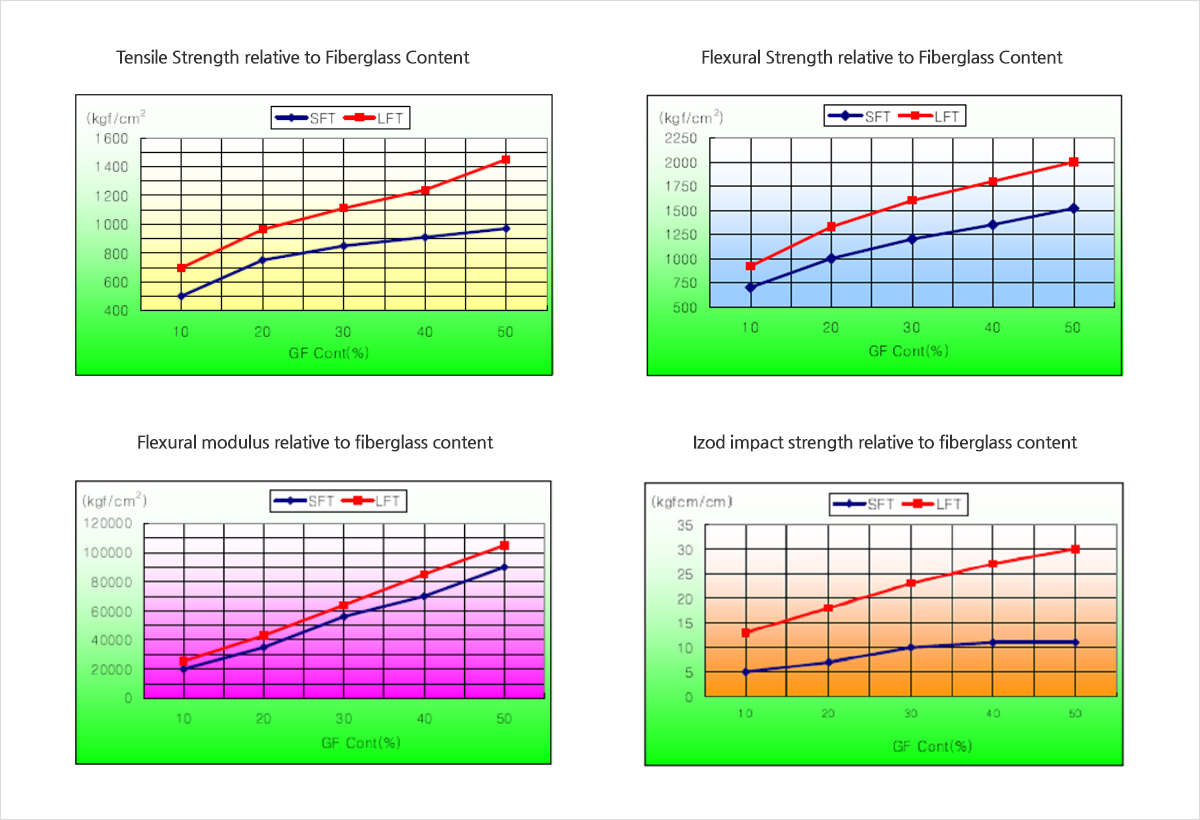

Comparison of Properties between HISTRON and SFTP

Comparison of Properties between PP (polypropylene) based LFTP (HISTRON) and SFTP

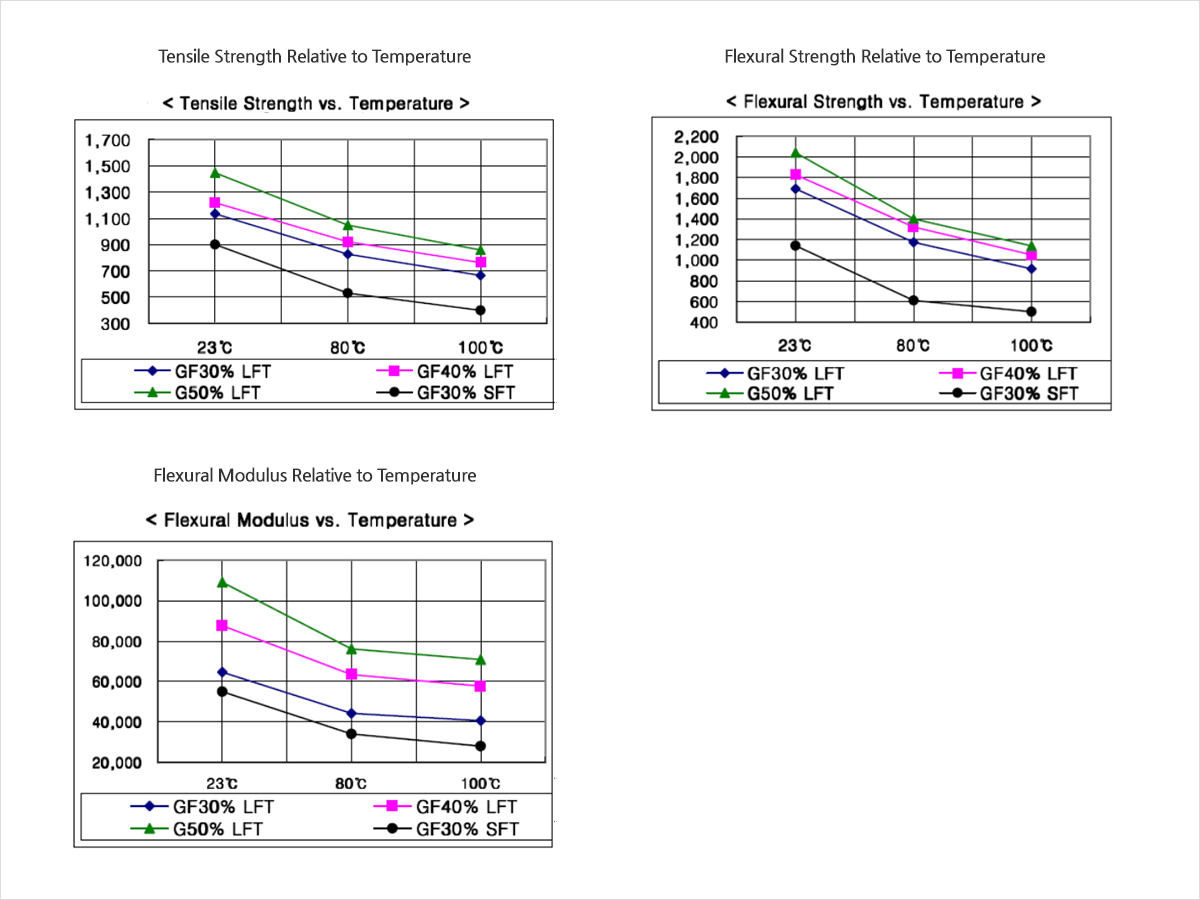

Temperature Dependence of HISTRON and SFTP

PP (polypropylene) based LFTP (HISTRON) for Automobiles

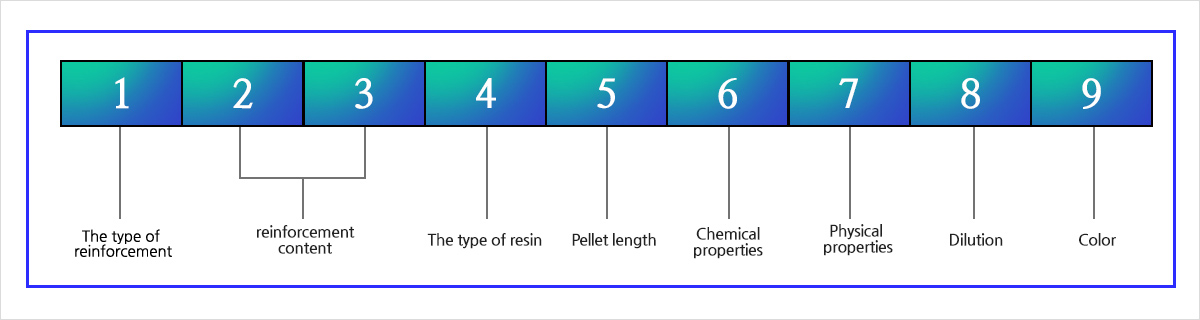

HISTRON Naming Method

- 1) The name of a HISTRON product is 9 characters long and consists of a combination of alphanumeric characters.

- 2) KANGNAM KPI provides a variety of reinforcement (fiberglass and carbon) , reinforcement content (20-70%), resins (PP, PA6, PA66, ABS, PC, PBT), pellet lengths (6 -25mm), required characteristics (weather resistance and flammability), colors, etc. according to customer needs. e.g.) The HISTRON named G40P2GB1N is LFT with the following characteristics: the resin applied, PP; fiberglass content, 40%; the pellet length, 12mm; and the color, natural. The HISTRON named G30A2BB1B is LFT with the following characteristics: resin applied, PA6; fiberglass content, 30%; the pellet length, 12mm; the color, black; and weather resistant.

HISTRON Properties Table

- 1) In addition to the products shown below, KANGNAM KPI can also produce and supply products with various other matrixes and properties according to customer demand.

- 2) Be sure to consult KANGNAM KPI’s technical manager before selecting HISTRON’s grade.

| Item | Fiberglass conten | Specific gravity | Tensile strength | Flexural strength | Notched Izod impact strength | HDT | Characteristics and application | Data Sheet | |

|---|---|---|---|---|---|---|---|---|---|

| Unit | % | - | kgf/cm2 | kgf/cm2 | Kgfcm/cm | ℃ | |||

| Test Method (ASTM) | - | - | D638 | D790 | D256 | D648 | |||

| HISTRONGRADE | G30P2BB1N | 30 | 1.1 | 1,042 | 1,664 | 22 | 153 | Matrix: PP, weather resistant, and used for automobiles |

View technical sheets Request MSDS’s |

| G40P2BB1N | 40 | 1.21 | 1,246 | 1,878 | 27 | 158 | |||

| G50P2BB0N | 50 | 1.32 | 1,362 | 1,978 | 31 | 161 | |||

| G60P2BB0N | 60 | 1.41 | 1,406 | 2,013 | 33 | 163 | |||

| G30P2GB1N | 30 | 1.11 | 1,104 | 1,619 | 21 | 151 | Matrix: PP and used for general products and industrial products | ||

| G40P2GB1N | 40 | 1.2 | 1,262 | 1,844 | 26 | 156 | |||

| G50P2GB1N | 50 | 1.31 | 1,310 | 1,937 | 29 | 159 | |||

| G40A2GB0N | 40 | 1.46 | 2,080 | 2,844 | 34 | 212 | Matrix: PA | ||

HISTRON Forming Technology

- 1) For HISTRON to maintain its original properties, the length of its reinforcing fibers needs to be maintained as much as possible. This is because the physical properties of the final molded product depend on the length of the fibers. Therefore, it is recommended to set the injection speed and the screw speed as low as possible and be sure that the molding machine meets the following requirements.

- 2) Requirements for HISTRON injection molding machines

| Item | Requirements | |

|---|---|---|

| Screw | Composition | The machine must consist of more than 3 zones including a metering section, a compression section, and a supply section, and temperature control needs to be possible for each zone. |

| 3 zone proportions | The metering section, 20%. The compression section, 30%. The supply section, 50%. | |

| Diameter | At least 20mm. 40mm or more for optimal results. | |

| L/D | 1.8:1 ∼ 22:1 | |

| Compression ratio | 1.8:1 ∼2.5:1 | |

| Flight depth | The metering section, at least 3mm. The supply section: at least 4.5mm. | |

| Nozzle | Diameter | At least 4mm. 6mm or more for optimal results. |

| Mold | Sprue | Design the machine so that it has the shortest sprue length possible. |

| Runner diameter | At least 4mm. 6mm or more for optimal results. | |

| Gate diameter | At least 3mm. | |

3) HISTRON pre-drying conditions

* It is recommended to dry HISTRON before use to attain products of better quality.

| Base | Drying Temperature (℃) | Drying time (hr) | Note |

|---|---|---|---|

| PP | 80 | 2 | * If there are no problems regarding storage of this type of HISTRON (e.g. when storing it in a dry indoor place), you can use it without any drying process. |

| PA | 90 | 4 | * PA is naturally prone to absorb moisture. Therefore, be sure to dry this type of HISTRON before use. |

4) HISTRON injection molding conditions

* Be sure to set the injection speed, injection pressure, and screw speed as low as possible.

| Base | Injection pressure | Injection speed (mm/ sec) |

Screw speed (RPM) |

Cylinder temperature (℃) | Mold Temperatures (℃) |

Note | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Resin | G/F content (%) | Supply section |

Compression section |

Metering section |

Nozzle | |||||

| PP | 30 | 600 ~ 1200 | 30 ~ 60 | 30 ~ 80 | 200 | 210 | 215 | 220 | 60 ~ 80 |

* It is recommended to set the screw speed below 60RPM. * With regard to product exteriors, it is recommended to set the mold temperature high. |

| 40 ~ 80 | 210 | 215 | 220 | 220 | ||||||

| 50 | 215 | 220 | 225 | 225 | ||||||

| 60 | 220 | 230 | 240 | 240 | ||||||

| PA | 40 | 1200 ~ 1500 | 40 ~ 75 | 30 ~ 80 | 255 | 260 | 265 | 270 | 80 ~ 90 | |

| 50 | 260 | 265 | 270 | 275 | ||||||

| 60 | 265 | 270 | 275 | 280 | ||||||