SMC (Sheet Molding Compound)

SMC is a thermosetting composite molding material in sheet form, created by impregnating glass fiber stiffener into a resin compound of unsaturated polyester resin and additives that include low profile agents, lubricants, and fillers and then increasing the viscosity of the resin compound using chemicals.

-

The Characteristics of SMC

- 1) SMC has excellent mechanical strength.

- 2) SMC has good workability ; it is easy to handle and also easy to inject into molds due to its non-stickiness.

- 3) SMC has excellent productivity; SMC makes it possible to product large quantities of products in a short amount of time compared to the existing FRP molding method.

- 4) SMC has excellent levels of stain resistance, water resistance, weather resistance, and corrosion resistance.

- 5) SMC has high heat deflection temperatures and suffers little thermal aging.

- 6) SMC comes in various colors.

- 7) SMC is guaranteed to have a semi-permanent lifespan; SMC can be used for long periods of time because it does not rust or corrode easily compared to metal and wood.

- 8) SMC has excellent dimensional accuracy.

SMC grades with low - or non-shrink properties can be used for precision parts.

-

Handling Precautions

Storage

- 1) Avoid storage places with high temperatures and store SMC at a temperature of 20℃ or below.

- 2) Avoid direct sunlight and store SMC in a cool dark place.

- 3) Ensure that SMC’s packaging is not damaged during its storage.

(Damaged outer packaging volatizes SMC, making it unusable.)

At Work

- 1) Ensure that SMC does not come into contact with direct sunlight or moisture at the work site.

- 2) Be sure to store only the day’s production of SMC at the work site if possible.

- 3) Be sure to use the material immediately after removing its packaging (AL film).

- 4) When SMC is to be left unattended for more than 30 minutes after its PE/PP film is removed, be sure to re-wrap it with Al film prior to storage.

- 5) Be sure to wear a dust mask and protective glasses before commencing work.

-

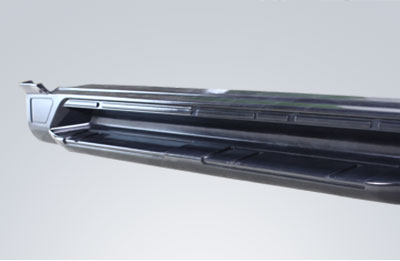

SMC Products

Product Specifications

- Form: Sheet

- Width: 1000mm (600-1000mm available by special order)

- Thickness: 2.0-4.0mm

- Package: 100kg/Roll or 1 M/T

- Building Materials and

UBR Sectors - Heavy Electrical Equipment and Industrial Sectors

- Automotive Sector

- Defense Industrial Sector

Our SMC products in this line are used for internal and external auto parts.

| Grade | Application | Colors | Data sheet |

|---|---|---|---|

| KT 2011 | Spoilers for cars, bumpers and sliding door panels for buses, front lid panels for commercial cars, overhead stowage, and side door panels for heavy electrical equipment | Natural, White, and Ivory |

View technical sheets Request MSDS’s |

| KE 2041 | Dash panels, fork lift hoods, and chairs and covers for farm machinery | Gray | |

| KA 1011 | Shell plating for cars |